The sructural introduction of Diesel Engines

2025-05-30

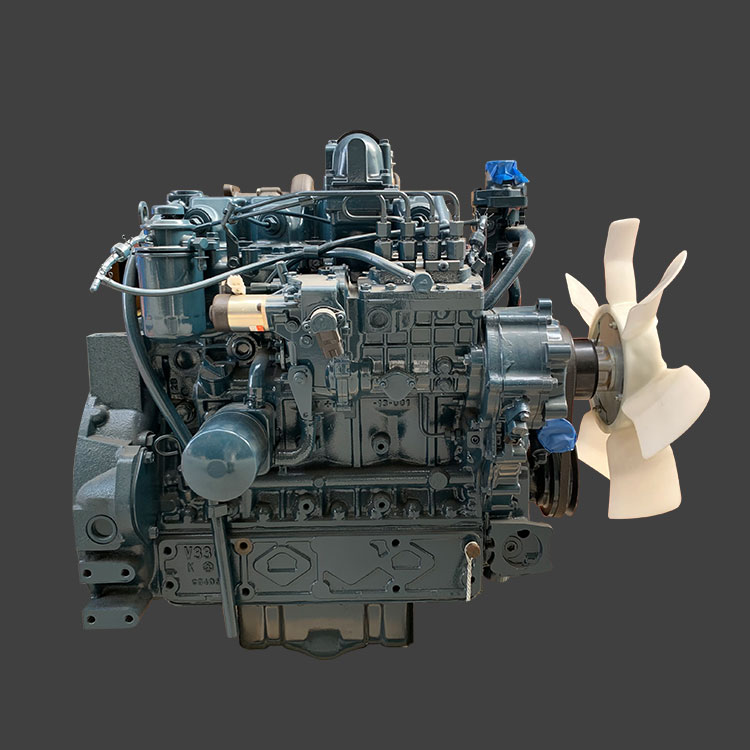

A diesel engine is an internal combustion engine that uses compression ignition to burn fuel. Unlike gasoline engines, which use spark plugs, diesel engines rely on the heat generated from compressing air to ignite the diesel fuel. These engines are widely used in transportation (trucks, ships, trains), power generation, and industrial machinery due to their efficiency and durability.

1. Basic Structure of a Diesel Engine

A typical diesel engine comprises the following main structural components:

a. Cylinder Block

The main body of the engine.

Houses the cylinders where pistons move up and down.

Contains passages for coolant and oil to maintain optimal temperatures and lubrication.

b. Cylinder Head

Attached to the top of the cylinder block.

Contains the combustion chamber, intake and exhaust valves, fuel injector nozzles, and sometimes the camshaft.

Sealed to the cylinder block with a head gasket.

c. Pistons

Move up and down inside the cylinders.

Transfer energy from the combustion of fuel into mechanical work via the connecting rod.

d. Connecting Rod

Connects the piston to the crankshaft.

Transmits the reciprocating motion of the piston into rotational motion.

e. Crankshaft

Converts the linear motion of the pistons into rotational motion to drive the vehicle or machinery.

Typically supported by bearings within the crankcase.

f. Fuel Injection System

Precisely injects diesel fuel into the combustion chamber at high pressure.

Includes components such as the fuel pump, injectors, and fuel lines.

g. Valvetrain

Includes intake and exhaust valves, camshaft, rocker arms, and push rods.

Controls the flow of air into and exhaust gases out of the combustion chamber.

h. Turbocharger (Optional)

Increases the engine’s efficiency and power output by forcing extra air into the combustion chamber.

i. Cooling System

Uses coolant circulated through the engine to prevent overheating.

Includes the radiator, water pump, thermostat, and coolant passages.

j. Lubrication System

Reduces friction and wear between moving parts.

Comprises an oil pump, oil filter, and network of oil passages.

2. Working Principle

The diesel engine operates through a four-stroke cycle:

Intake Stroke – Air enters the cylinder as the piston moves down.

Compression Stroke – Piston moves up, compressing air, raising its temperature.

Power Stroke – Diesel fuel is injected and ignites due to the high temperature, forcing the piston down.

Exhaust Stroke – Burnt gases are expelled as the piston moves up.

3. Structural Advantages

High thermal efficiency: Due to higher compression ratios.

Robust construction: Designed to withstand higher pressures and temperatures.

Durability and longevity: Diesel engines typically have a longer operational life than gasoline engines.

If u are interested in our products, welcome to contact us. We will contact you in 24 hours.