Why is the Parallel Comb Idler Essential for Modern Conveyor Systems?

2025-09-12

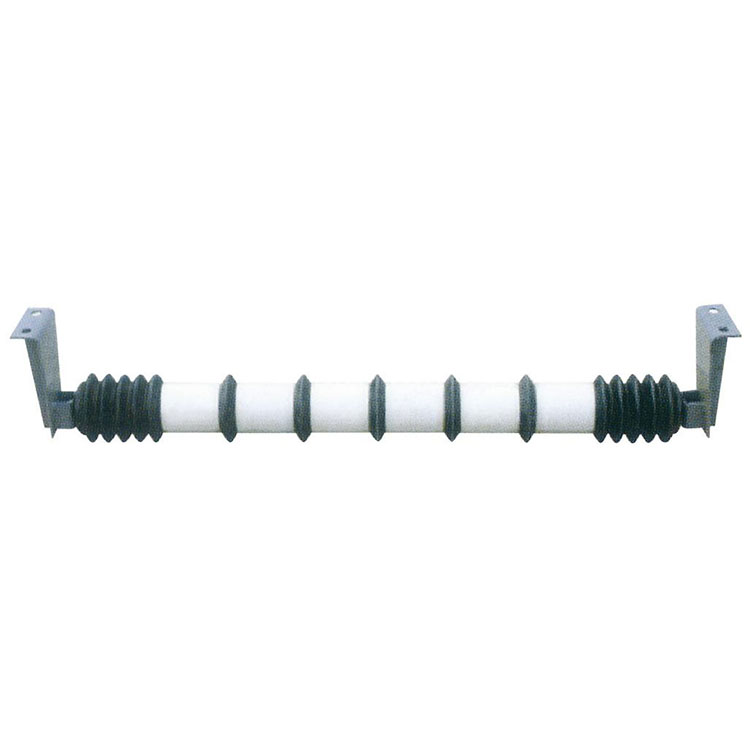

In industrial conveyor applications, efficiency and reliability are critical. One component that often goes unnoticed but plays a vital role in smooth operations is the Parallel Comb Idler. This specialized idler is designed to manage belt alignment, reduce material build-up, and extend the service life of the conveyor system. As a professional in the field, I have seen how a well-chosen Parallel Comb Idler can prevent downtime and lower overall maintenance costs. But what exactly makes it so effective, and why should businesses prioritize it? Let's explore.

What is the Function of a Parallel Comb Idler?

The Parallel Comb Idler is a precision-engineered conveyor accessory that ensures stable belt tracking and efficient material discharge. It is commonly used in industries such as mining, steel, cement, and ports where heavy-duty conveying is essential.

Main functions include:

-

Keeping the belt centered and preventing deviation.

-

Cleaning loose material from the belt to avoid spillage.

-

Reducing wear and tear on the conveyor system.

-

Increasing operational efficiency by maintaining continuous belt motion.

How Does It Perform in Real Applications?

The performance of a Parallel Comb Idler is directly linked to improved productivity. When installed correctly, it prevents excessive belt misalignment, which can otherwise cause downtime and safety risks.

Performance effects:

-

Improved Belt Life – Consistent cleaning and alignment reduce premature belt damage.

-

Reduced Maintenance – Less material build-up means fewer shutdowns for cleaning.

-

Energy Efficiency – Smooth running of the belt reduces energy consumption.

-

Operational Stability – Even under heavy loads, the idler ensures steady transport.

Why is the Parallel Comb Idler Important?

The importance of this component lies in its ability to enhance overall system reliability. A conveyor system without an efficient cleaning and alignment mechanism risks frequent interruptions. By installing a Parallel Comb Idler, companies can achieve:

-

Lower operating costs.

-

Higher system safety.

-

Consistent material handling.

-

Better return on investment.

Question and Answer Perspective

Q1: Why should I consider using a Parallel Comb Idler in my conveyor system?

A1: Because it minimizes belt misalignment, reduces spillage, and extends equipment lifespan. In my own experience, replacing traditional idlers with Parallel Comb Idlers drastically cut down on downtime.

Q2: How does the Parallel Comb Idler improve safety in operations?

A2: It prevents belt slippage and material overflow, reducing the chances of accidents. I have seen how operators feel more confident working near conveyor lines equipped with this technology.

Q3: Can the Parallel Comb Idler lower overall costs?

A3: Yes. By reducing maintenance requirements and preventing early belt wear, it directly saves money. I always recommend it to clients looking for long-term operational efficiency.

Technical Overview

Here is a simplified technical table to illustrate its practical features:

| Feature | Description | Benefit |

|---|---|---|

| Structure | Parallel comb design with durable steel | Strong and long-lasting |

| Function | Belt cleaning & alignment | Reduces material build-up |

| Application Industries | Mining, steel, cement, ports, power plants | Wide adaptability |

| Maintenance Requirement | Minimal | Saves time and labor |

Final Thoughts

The Parallel Comb Idler is more than just an accessory—it is a key factor in the efficiency, safety, and reliability of conveyor systems. Its ability to maintain belt stability, reduce costs, and extend system longevity makes it indispensable for industries that rely on heavy material handling.

If you are searching for high-quality conveyor components, Jiangsu Wuyun Transmission Machinery Co., Ltd. provides advanced solutions with proven reliability. Their expertise ensures that every Parallel Comb Idler meets the demands of modern industries.

Contact Jiangsu Wuyun Transmission Machinery Co., Ltd. today to upgrade your conveyor system with professional-grade components.